TAPER TIP SHAFT OR PARALLEL TIP SHAFT

The difference between a parallel tip shaft and a taper tip

shaft is the tip diameter and shaft weight. All golf shafts

taper from the butt to the tip, but parallel tips stop

tapering below the last step, while the taper tips, continues

to narrow. The taper tip was the only choice until the 1970s,

when the parallel tip came on the market. Parallel gradually

gained favor with club makers, and since 1990s has been the

favored shaft choice.

For years and years, the steel iron shaft most used by tour players was the DYNAMIC TAPER TIP SHAFT from True Temper. Shafts evolved as taper tip in nature for one reason only - to add a form of mechanical lock to the poor quality glues of the late 1800s and all through the early to middle 1900s. However, by the 1960s epoxies had been introduced to the world with holding strengths that were far greater than had previously been seen in the adhesive industry.

All through the middle 1950s, every taper tip shaft produced required the golf companies to buy a different raw length for each head number. What's more, each different length raw shaft also had to be bought in a single flex. Thus if a golf company was building R and S flex woods and irons in a 1,2,3,4 wood and 2-PW irons, they had to buy and stock 26 different shafts to build the sets. If they were out of stock in 1 or 2 of these shafts, they could not finish the sets.

A characteristic of the Dynamic taper tip shaft is that each different raw length, used to make each different numbered iron in a full set, was actually made to the same weight. As a result, the tip cannot be trimmed without changing its diameter, meaning it would not fit in the club head. The standard tip diameter for a taper tip iron shaft is .355 inch, slightly smaller than a parallel tip. Each taper tip shaft is built to length for a specific iron and is the same weight throughout the set of irons

Most of the forged irons from all the OEMs (Original Equipment

Manufacturers, ie TaylorMade, Ping, Nike) were offered with

the Dynamic iron shaft because that is what the tour players

most often used. Since the tour players liked the taper tip

Dynamic, the OEMs stayed with this shaft in their forged irons

and all the heads were made with a tapered bore. The Dynamic

pattern from True Temper is one of the very few steel shafts

in which the taper tip version weighs the same for each shaft.

This happened of course because when you use one master shaft for every head, you cut more from each iron shaft from the long to the short iron clubs. This changed the balance point of the clubs when built with the Dynamic parallel tip version vs. the taper tip version. With a parallel tip shaft, the narrowest portion of the shaft is a constant diameter, but not a constant weight. While the size does vary between manufacturers, the industry standard for irons is .370 inch. Golf clubs are different lengths within the same set; the higher-numbered irons are shorter than the lower-numbered irons. Because the club maker starts with the same shaft and trims it for each iron, the weight of the shaft changes.

Pretty much every other taper tip steel iron shaft today is made from a parallel tip blank model. After trimming to the different shaft lengths required for each head number, the shaft companies then squeeze down the parallel tip into a tapered configuration. The reason is because it is FAR less expensive to make a set of taper tip shafts from a parallel blank than it is to make each taper tip shaft from its own separate tooling so each shaft could weigh the same. So this means when you see a set of taper tip iron shafts in a set of irons off the rack and the shaft is not a True Temper Dynamic, it’s a waste of time for them to do this, since the tapered and parallel versions are the same.

But not in the True Temper Dynamic, so that still stands as the main reason why many OEM forged irons are tapered bore, that and the old tradition that “good players use taper tip iron shafts.”

TRUE TEMPER DYNAMIC GOLD IDENTITY

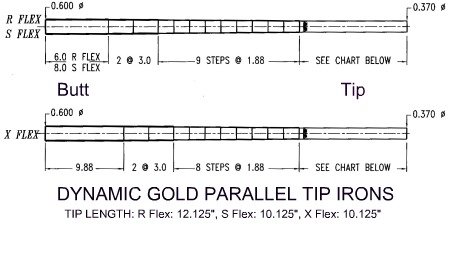

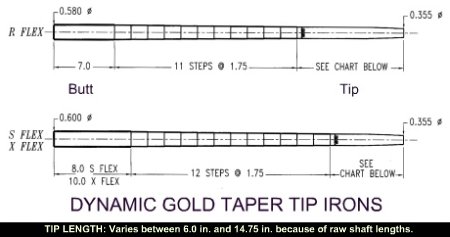

If you have True Temper Dynamic Golds in your irons, the diagrams below will help you identify whether your shafts are taper tip or parallel tip.

The main difference we have found is: Look at the steps immediately below the grip. Notice that parallel tip shafts have two 3.0” steps before 9 or 8 equal steps, and the taper tip shafts have 11 or 12 steps all at the same length.

We hope this has helped you understand the difference between taper tip shafts and parallel tip shafts. There will always be taper tip heads available, but we have found that more and more players are happy to switch to parallel. A good club maker would be happy to identify what you have and to recommend where to go.