GOLF IRONS FROM BLADES TO PING TOGAME IMPROVEMENT CAVITY BACKS

BLADE / TOUR IRON

Blade irons have been around and have remained mostly unchanged for over 100 years. They're simple, both in how they're designed and in how they respond to different shots, and even today, blades are considered by many to be the most traditional, classy style of club available.

The earliest golf clubs were constructed of wood, because iron clubs would have damaged the leather, feather-stuffed golf balls being used back then. However, right around the middle of the 19th century, a harder ball was developed, and because of these new, more durable balls, club heads began being constructed out of iron.

The benefits of using iron constructed heads was profound because the heads could be shaped differently. Originally, iron club heads were forged by hand, usually by a blacksmith. They get the name "blades" because early club heads constructed this way really did look like a blade due to their angular features. As time progressed, the process of forging blades became somewhat more sophisticated, even though blades today still have the same core features as those that were made 150 years ago.

From the 1940s through the 1970s, blades were the golf standard. From the 1980s and up through today, other more-forgiving clubs have started to become more popular. This is perhaps because of new advances in club design and technology that allow new clubs to perform nearly as well as traditional blade irons while still being forgiving and consistent. Until recently, forged clubs were synonymous with blade clubs, but nowadays there are cavity back clubs that can be forged as well.

Despite being considered some of the most traditional golf clubs, the future of blades is somewhat uncertain. It's expected that the number of recreational golfers will continue to grow as it has during the past few decades, and as a result, clubs that have been specially designed for mid to high handicap golfers, ie; muscle-back blades in order to make the game more enjoyable will also become more prevalent. Even among the pros, the blades are beginning to lose their popularity

However, being some of the first iron golf clubs, blades are a staple of the golf world. While it is true that some professionals are beginning to favor game-improvement clubs , thus far, no other club on the market is able to offer the buttery soft feel that forged blades are famous for. Until that day comes, blades will continue to be favored by many professional golfers so they can get the feel and performance they're used to, along with the simple, traditional appearance.

THEN ALONG CAME KARSTEN "PING" AND "PERIMETER WEIGHTING"

Located in Phoenix, Arizona, Karsten Manufacturing Corporation is famous for its Ping golf clubs. Founded by engineer Karsten Solheim, the company has been at the forefront of golf innovation since the development of the Ping putter in the late 1950s. A tennis player, he never even tried golf until 1953 at the age of 42, he played a round with coworkers and became enamored with the game.

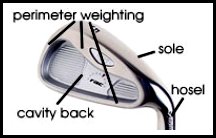

Putting was particularly troubling to Solheim, who soon concluded that a large part of his difficulties could be attributed to design flaws in his putter, which no matter how consistently he stroked it would TWIST just enough to send the ball off course. Knowing that a tennis racket employed perimeter weighting, in which the weight was distributed to the rim to allow the strings to provide greater power, Solheim decided to apply the same principle to the putter. By putting most of the weight at the heel and toe of the putter's blade he would be able to create a forgiving "sweet spot" in the center, allowing the player a much better chance to hit the ball straight.

In 1962 Solheim received a patent on the heel-toe weighting design on his putter, and In January 1966 an idea for a new putter came to him in a flash of inspiration. His wife Louise thought the new putter should be called "answer," a name that Solheim liked but that possessed too many letters to fit on the club. She then suggested that the "w" be left out. The legendary "Anser" putter, used by countless tournament winners, was born, and Karsten Solheim was on the verge of finally quitting his day job, but continued to work on improving the design while also beginning to develop irons.

Solheim's work on irons came to fruition in the late 1960s. He applied the heel-toe, perimeter weighting principle from his putters to fashion a sweet spot and also employed investment casting, which was far more precise than the popular forging method. Because he lacked access to a wind tunnel, he had a son drive him 100 miles an hour in the desert in order to hold his prototype out the window to check the drag caused by a typical swing.

Other equipment makers produced shinier clubs, making Karsten clubs look almost homemade, and once again Solheim insisted that his clubs be judged by their results. He refused even to add chrome plating in order to please customers. Performance eventually converted the reluctant, and that performance was enhanced by other Solheim innovations. He heat-treated the clubheads to resist corrosion and add strength, but it also allowed them to be adjusted for loft and lie, meaning the clubs could be custom fitted to take into account the customer's stance and swing. In the early 1960s Solheim had calibrated loft and lie angles for pro golfers, work that now led to the creation of the Ping Color Code Fitting System.

Between 1969 and 1976 the company came out with its Karsten I, II, III, and IV irons, followed by the popular Eye series starting in 1979, the Ping Zing Series, and the rest is history.

|

|

|

| Ping I Original | Ping Eye 2 | Ping Zing |

I divide Pings into three groups, the original irons, 1 – VI and original Eyes, as the first group (simple cast clubs with small cavity backs and varying sole weighting), the second group as the Eye2 – ISI models (more complex castings, cavity back with varying perimeter weighting) and the third group as i3, 13+, G2, and I5/G5 (cavity back with a tuning port), S57, S58 and S59 we’ll call Blades. Rapture, Rapture V2, G/15 – G/i15 might start a new generation with emphasis on toe-weighting. It seems that the Ping Eye series is the most popular of all, as I continually see customers bring these in for maintenance. Maybe Ping is going marketing like the rest of the O.E.Ms.

Karsten Solheim was acknowledged by all as one of the most important influences on golf club development in the modern era. His sons now lead the company he created and a third generation was preparing to carry on his commitment to innovation and craftsmanship.

GAME IMPROVEMENT CAVITY BACK

After Mr. Solheim proved to the golf world that his inventions were everything he claimed them to be, this opened the floodgates for manufacturers to start inventing to-day’s multitude of game improvement irons.

Cavity backs offer a large sweet spot which makes contact will the ball easier and as a consequence will "correct" slightly mis-aligned shots. This is called "forgiveness" and it is what these clubs are famous for and have been marketed as providing. The bottom line is that they make it easier for you to hit the ball straighter and with distance more consistently - they are assistive.

Game improvement irons, the concept for which originated in the 1980s, take this important part of your game and provides you with a set of clubs that have the sole purpose of combining forgiveness with playability...to enable you to hit the ball further, straighter, more consistently and hence with more confidence so that you can make real improvements in a much shorter period of time than you would if you were trying to progress using a professional level set of blades or a more traditional iron.

All of the different iron sets available on the market incorporate the same fundamental core technological features like perimeter weighting, a large sweet spot and a low center of gravity.

The purpose of these features is to counter any mis-alignment on contact with the ball (ie to prevent or reduce the severity of a hook or a slice), to give you the largest contact area possible so that maximum distance is always achieved and to prevent or reduce “topping” as loft and hence height of the ball after contact plays a significant part in the end distance of any particular shot. The trade off for using such irons that are “corrective” in nature is that you do lose some of the ability to manipulate the ball – you lose some of the “feel” as it is often referenced.

WHERE TO FROM HERE ???

Is there more to come? Probably! The little gnomes that spend all day designing heads, will probably come up with lots of inventions over the coming years, more marketing hype than technology, but we have found what we believe is in an iron head that gives you everything all in one.

Our featured Wishon 565MC iron head is a forged blade design with all the perimeter weighting built in. It has the look of a blade, the feel of a blade (made from carbon steel), and has become a new benchmark in iron design. Click on the image for a more thorough look.

A Walk Thru Iron Evolution

Return to Home Page